Polyester Silk Screen Printing Mesh Fabric Sheet 160M 64T

Silk Screen Mesh. The silk screen mesh is the foundation of the printing process. It is a fine, woven fabric that is stretched tightly over a frame. The mesh is available in a variety of materials, including polyester, nylon, and stainless steel. The mesh size determines the level of detail that can be printed.

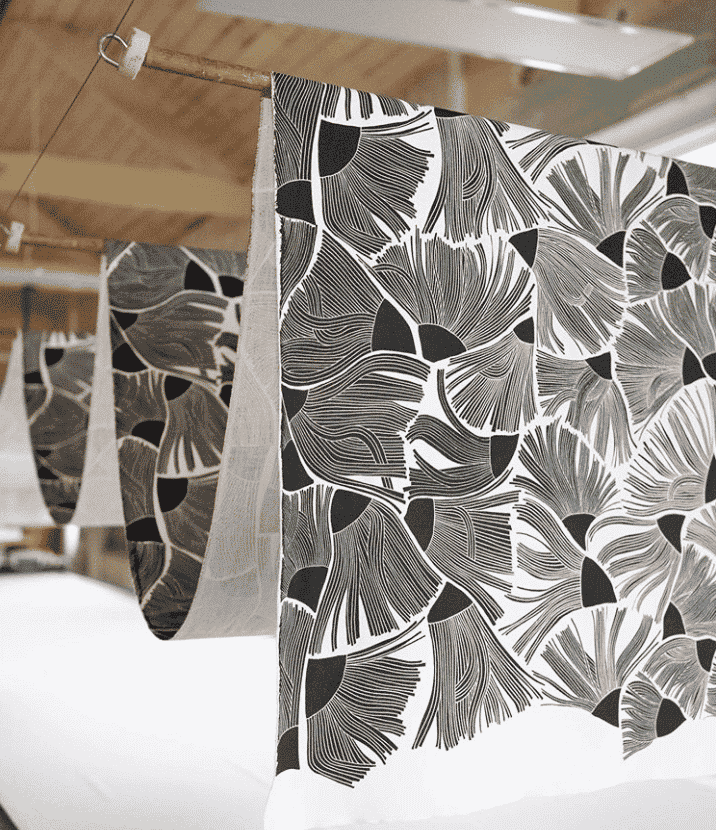

Cotton Screen Printed Fabric Weaveron

Screen printing is the process of transferring a stencilled design onto a flat surface using a mesh screen, ink and a squeegee. Fabric and paper are the most commonly screen-printed surfaces, but with specialised inks it's also possible to print onto wood, metal, plastic, and even glass. The basic method involves creating a stencil on a fine.

Advantages and Limitations of Screen printing Textile Apex

Place your printing medium (pigment or dyes etc) along the bottom of your screen (closest to you). Using a squeegee, pass the printing medium from one end of the screen to the other. Carefully lift the screen to reveal your design. There are a number of different printing mediums you can use including:

Fabric Screen Printing Service, Rs 30/meter Indigo Line ID 20312574933

Screen printing ink is a thick, pigmented ink that is designed to be pushed through a fine mesh screen, while fabric paint is a thinner, more fluid paint that is designed to be applied directly to fabric using a brush or other applicator. Screen printing ink is more durable and long-lasting than fabric paint, making it a better choice for.

How to screen print on different kinds of fabrics Permaset

Step 7: Print Your Design. Pour a small amount of screen printing ink onto the screen, next to your design. Hold the squeegee at a 45-degree angle and pull it across the screen, pressing the ink through the mesh and onto the fabric. Make sure to apply even pressure to achieve a consistent print.

screen printed fabric screenprinting Pinterest Design, Hands and Fabrics

Screen printing is the technique of pushing ink through a stenciled mesh screen to create a printed design, blending creativity and precision. The traditional yet dynamic method, revered for its versatility and vivid results, has become a cornerstone in the world of printing. This article unpacks the vibrant advantages, diverse applications.

DIY screen printing Learn how to screen print with Erin Dollar Blog Diy screen printing

R A Smart is dedicated to bringing to life the creations, dreams and aspirations of designers around the world, RA Smart has re-defined the 'art' of fabric printing and are acknowledged experts in the fields of specialist digital and screen print for the textile industry. Established for over 50 years, We offer a UK screen printing service.

How to Screen Print a Cotton Fabric by Hand in 5 minutes YouTube

1. Telio Organic Cotton Jersey Knit. This organic cotton jersey knit is made from 100% cotton. Cotton works great for screen printing because it is a natural fabric and organic cotton is also great for the environment. While cotton is known to be soft, this organic cotton is even softer and drapes well. 2.

Pllieay 62PCS Complete Screen Printing Kit Include Fabric Screen Printing Ink & Photo Emulsion

Step 3. Printing your design. This step involves the actual application of ink through the stencil onto the fabric. Ink is applied directly to the surface of the fabric through this screen. Consistency in ink application is key to achieving a vivid and uniform print. Fabric is stretched on a flat surface.

BUY Fabric Screen Printing Ink 8 Oz Brown

With very little investment and almost no technical knowledge or complex apparatus, we will get you started on screen printing. It's a common misconception t.

Screen Printing on Fabric Screen Printing Fabric Fabric Screen Printing Machine Screen

Screen printing is an art form that has been around for centuries, offering a unique way to apply designs onto various surfaces, including fabric. While there are several methods for printing on fabric, screen printing stands out for its versatility, durability, and the high-quality results it produces. Whether you're

Speedball Fabric Screen Printing Ink

The mixed inks will leave the fabric soft and washable. Here's how to mix them: Start with Fabric Screen Printing Binder . This is a colourless screen printing medium and will form the base of our ink. Use a clean spoon to decant some of the binder into a pot. Next, add the Pigment Colour.

Silk Screen Printing Guide on Silkscreen Printing Sunrise Metal

Silk screen printing mesh / fabric: Finest quality, swiss made, polyester monofilament screen mesh / fabric. Used for screen printing. Read More. Screen Printing Inks - Daler Rowney. Daler Rowney System 3 Inks All colours are 500ml Next Day Delivery LEMON YELLOW £9.94 PROCESS YELLOW £9.94 CADMIUM YELLOW.

1 Yard 180 Mesh Count(72T)Screen Fabric screen printing material screen printing framein Copy

To see what you are doing, use a red photo-darkroom light. [1] 4. Let it dry in a completely dark place overnight. 5. Spread the black paper all over the floor and put your screen on top, wood side down (with staples on top). 6. Tape your transparencies with clear tape to the dry surface of the screen.

BUY Fabric Screen Printing Ink 8 Oz Proc. Yellow

2. Creating The Stencil. With a mesh screen suitable to the design and the surface being printed, you will need to coat the screen with light-reactive emulsion, which will cure under bright light. The acetate film, which contains the design, will then lay on top of the coated mesh screen.

Screen Printing Fabric Silk Screen Printing Fabric

VEVOR Screen Printing Machine, 55x45cm Desktop Silk Screen Printing Machine, 17.7X 21.7 Inch T-Shirt Printing Machine, Manual Screen Printing Press for Clothing, Fabrics, Metals (4 Color 1 Station) 6. £15999. FREE Delivery by Amazon.