Construction Laser Level Rotary Lasers Spectra Precision Laser LL300 Automatic Selfleveling

In this video tutorial Calvin explains what's in a typical self-leveling laser level and how it works. He also explains how to readjust a laser level when i.

Laser Level Repair, Construction Laser Repair, & Surveying Equipment Repair & Calibration

Our certified laser level repair center specializes in the repair and calibration of all types of laser levels, including rotary, grade, and pipe lasers. With experienced technicians and top-of-the-line equipment, they can troubleshoot and fix any issues you may have with your laser level. Our services include complete cleaning, diagnostics.

Upto 300 Meter Radius Theis Laser Level Rotatic Laser Level, 15 Deg C +50 Deg C at Rs 220000

Request your laser level calibration or repair service with our team of experienced technicians, with service centres in Brisbane, Sydney, Melbourne, Adelaide, Perth, Hobart, Canberra and Darwin we offer laser repairs and laser calibrations near you! Book A Service. Queensland. Brisbane 1075 Beaudesert Road (entry via Kerry Road).

2 Lines 360 degrees Laser Dumpy Level Horizontal Vertical Automatic Leveling Professional Laser

In this video tutorial, Calvin walks you through the entire process for checking the leveling accuracy of a 3D self-leveling laser. He shows you how to chec.

SNDWAY Laser Levels Green Laser Level Self Leveling Vertical Horizontal Lasers Cross Measure

Revolutionize your construction work with Spectra Precision Laser! The ultimate levelling and alignment tool for unbeatable accuracy and cutting-edge technology

Spectra Precision LL300N Laser Level Cody Corporation

Our calibration services ensure the accuracy of your equipment over time to a ISO 9001 certified level. Geosystems Division.. Explore our wide selection of on-demand webinars and register for upcoming webinars in our Laser Scanning Webinar Hub.. The demand for calibration certificates confirming the measurement quality of surveying.

SNAN 98 Feet Laser Level SelfLeveling Horizontal and Vertical CrossLine Laser, Three Modules

Karen Prawucki. Service Coordinator. (724) 266-1600. [email protected]. Authorized Warranty & Repair center with 25 Years in Service Repairs with Dedicated Customer Care.

Certified Laser Level Calibration w/Certificate

For more information on our lab or on-site calibrations, please use our Live Chat, located on the right side of the page. You can also Request a Quote , contact us, or call 800-828-1470 to speak to a member of our team. Laser Alignment Tool and System Calibration Services at Transcat. Calibration of laser shaft alignment tools.

Rotating Laser Level AutoLeveling for Construction RedBack Lasers

Whether you need laser level calibration service, engineer level calibration, or just to ensure that your level is meeting recognized standards, we can help. With Cross, you won't have to worry if your industrial levels are calibrated.. Find Level Calibration Near Me. Atlanta, GA. Atlanta, GA. Directions. Directions. 678.487.2050. 678.487..

Calibrate Laser Levels YouTube

Make sure that the level is stable and that the laser is projected horizontally. Take a measurement using a tape measure and mark it at one end. Then, rotate the level 180 degrees and take another measurement from the same point. If the distances are different, you will need to adjust the level.

Laser Level Calibration, Service & Repair RedBack Lasers

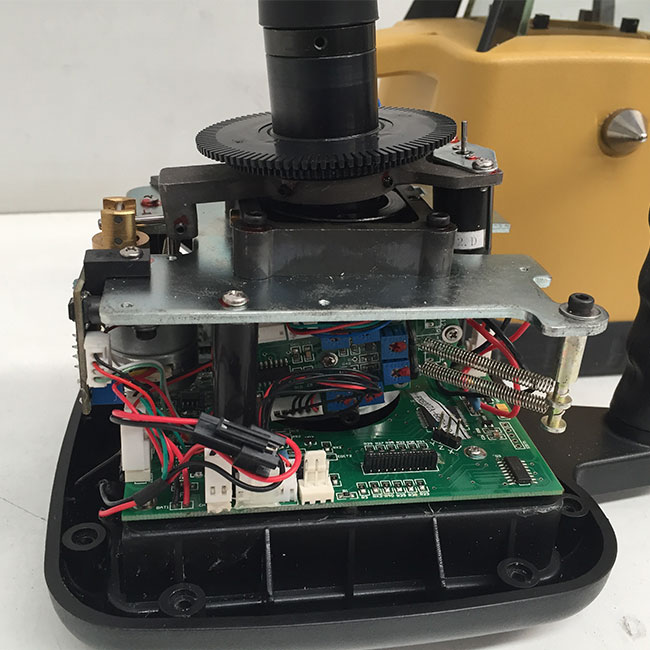

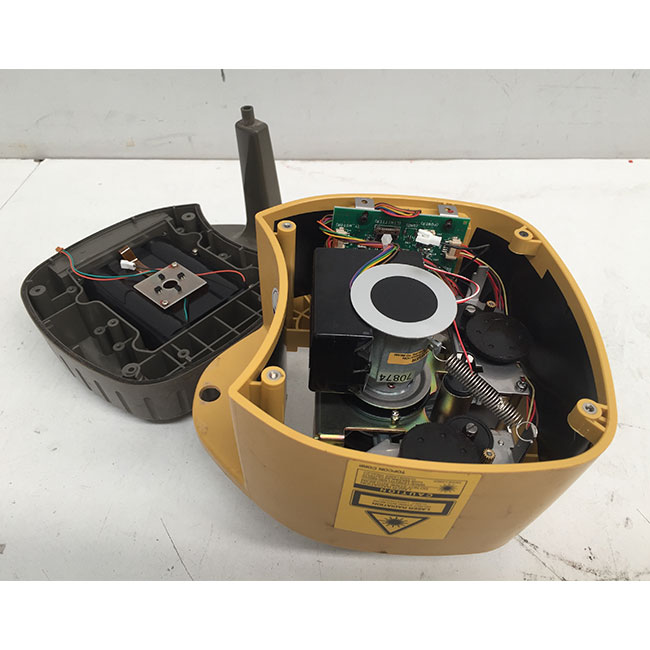

2. If manually calibrating, open up the level and check wires. Remove the batteries and open up the body of the level by removing all the screws. Gently tug at the wires with your screwdriver to make sure they are not hindering the pendulum in any way. Otherewise this will definitely throw off your level line. 3.

LL100N Laser Level NEI

The general recommendation, and again this is only a rough guide, is that a line laser, rotary laser or pipe laser should be calibrated a minimum of every 12 months to maintain its accuracy. However, if it is used frequently or daily such as a concreter with a rotary laser or a drainer with a pipe laser the laser level should be seen by a.

How to check your Laser Level Calibration RedBack Lasers

Place a piece of paper on the wall and mark the height of the laser. Next rotate the body of the laser 180° and again mark the height of the laser on the paper. If the two marks you have made are are exactly the same height then the calibration of the "X" axis is good. Note that the further away from the wall the laser is the more accurate.

Buy Spectra Precision LL300N Laser Level Kit including HR320 Detector, 4 Metre Staff, Surveying

We are certified to do repairs by most of the manufacturers we represent. Raleigh, NC. Monday - Friday: 8AM - 5PM. Concord, NC. Monday - Friday: 8AM - 5PM. Our specialists install, maintain, and service all major brands of lasers, total stations, drones and much more. Free Diagnostics. Customer-Oriented. 24/7 Support Available.

Scale Calibration Service & Repairs Australia Diverseco

We Calibrate and Repair All Makes and Models of Laser Levels, Construction Levels, and Surveying Equipment. Contact Our Service Center. for Service & Repair Estimates. For information about new equipment, call 800-591-8907. SERVICE REQUEST.

Laser Level Calibration, Service & Repair RedBack Lasers

Step 5: Rotate the Laser Level 180 Degrees. Carefully rotate the laser level 180 degrees without disturbing its position on the flat surface. Make sure the laser is still projecting onto the target. Now, measure the distance from the center of the laser beam to the floor again, and record this measurement in your notebook.