Concrete Floor Drawing at GetDrawings Free download

compensating concrete slabs-on-ground. The design of suspended floors should conform to requirements of ACI 318 and ACI 421.1R. See Section 1.2 for relevant work by these and other committees. This guide identifies the various classes of floors as to •Use; • Design details as they apply to construction; • Necessary site preparation; and

Concrete slab details M.Arch Pinterest Concrete slab, Concrete and Construction

Concrete Floor Specifications for Warehouses & Industrial Buildings. Understand specifications for industrial floor design, including concrete slab thicknessUpdated February 12, 2021. Residential concrete slabs often have few design requirements to get between the contractor and completion of the job. If the contractor knows what he or she is.

Soundproofing guidelines for approved document E compliance

The requirements for two of them are described in detail in ACI 318-14 Chapter 8 (8.2.1). Direct Design Method (DDM) is an approximate method and is applicable to two-way slab concrete floor systems that meet the stringent requirements of ACI 318-14 (8.10.2). In many projects, however, these requirements limit the usability of the Direct Design.

R403.1.3.2 Slabsonground with turneddown footings. This common construction detail relates to

Standard concrete floor slab thickness in residential construction is 4 inches. Five to six inches is recommended if the concrete will receive occasional heavy loads, such as motor homes or garbage trucks. To prepare the base, cut the ground level to the proper depth to allow for the slab thickness. Remove all organic material and large hard.

Concrete Slab Detail Cadbull

American Concrete Institute (ACI) 36 Times Slab Thickness. 6-in.-thick slab = 18 ft joint spacing. Portland Cement Association (PCA) Joint Spacing (ft) = 2 to 2.5 Thickness (in.) 6-in.-thick slab = 12 to 15 ft joint spacing. Maximum 30 Times Slab Thickness. 15 ft (4.5 m) Maximum ‐ Pavements.

Slab Construction Section View DWG File Cadbull

Concrete floor systems are reinforced slab structures designed to satisfy a range of loading and span conditions in a building.Designed to span in either one direction (one-way) or both directions (two-way) of a structural bay, the range of concrete floor systems available are created to economically and efficiently account for the numerous and specific demands of each building project.

Concrete Floor Slab Specification Flooring Ideas

mix, joint design and performance, and the slab thickness. Floor Classifications Table 1 describes the nine classes of concrete floors according to ACI 302, Guide to Concrete Floor and Slab Construction. This table details some of the special considerations and finishing techniques that are appropriate for each class of floor.

Pin on structuraldetails store catalogue

1.1—Purpose. This guide presents information relative to the construction of slab-on-ground and suspended-slab floors for industrial, commercial, and institutional buildings. It is applicable to the construction of normalweight and structural lightweight concrete floors and slabs made with conventional portland and blended cements.

Quadomated » Concrete Slab Detail

The quality of a concrete floor or slab is highly dependent on achieving a hard and durable surface that is flat, relatively free of cracks, and at the proper grade and elevation.. 5.3—Suspended slabs, p. 11 5.4—Miscellaneous details, p. 13 CHAPTER 6—SITE PREPARATION AND PLACING ENVIRONMENT, p. 14 6.1—Soil-support system preparation.

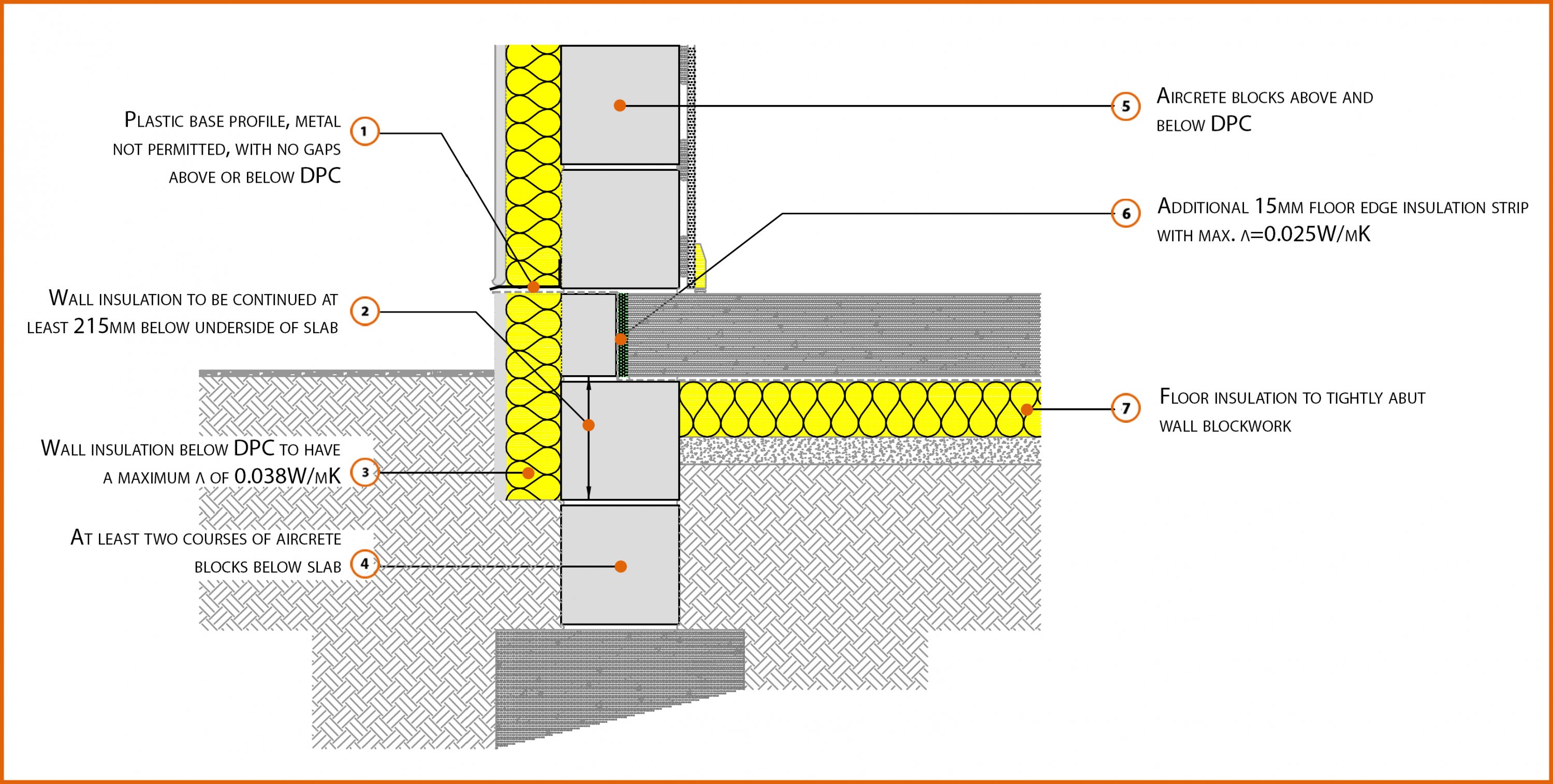

E5MCPF23 Concrete Ground Bearing Floor, Insulation Below Slab LABC

Hollowcore slabs are generally manufactured 1200mm wide, but can be cut narrower to suit particular applications. Slab Depths Slab depths typically range from 100mm to 500mm as shown below. Slab Profiles NOTE: Typical examples are shown; sections may vary in detail depending upon the manufacturer. Structural Performance

pre cast concrete floor steel frame detail Google Search Precast Concrete, Concrete Floors

The rebar running through the beams interlocked with the slab reinforcing and with the pier reinforcing. Once the concrete cured, the rebar in the slab and in the grade-beams created a self-supporting structure. The forms may crush over time, but the soil pressure will not be able to exert any significant force against the concrete. Grade beams.

pile foundation detail Google Search Concrete footings, Precast concrete, Concrete wall panels

Concrete Floor Slab Construction Process. 1. Assemble and Erect Formwork for Slab. The formwork shall be designed to withstand construction loads such as fresh concrete pressure and weight of workers and operators and their machines. Guide to Formwork for Concrete ACI 347-04 shall be followed for the design of formworks.

Concrete Floor TwoWay, Slab Dimensions & Drawings

T-SLAB ® is an all-new, patented precast concrete slab system that leverages the time-tested principles of Roman arch design and multiple concrete types to deliver a stronger, lighter, and more versatile slab. This groundbreaking product was designed to deliver all the advantages of concrete and the industry's most effective building materials in a single, cost-effective, and 100% precast.

02.***.**** Construction details architecture, Steel structure buildings, Architecture design

Two-Way Concrete Floor Slab with Beams Design and Detailing Design the slab system shown in Figure 1 for an intermediate floor where the story height = 12 ft, column cross-sectional dimensions = 18 in. x 18 in., edge beam dimensions = 14 in. x 27 in., interior beam dimensions = 14 in. x 20 in., and unfactored live load = 100 psf.

Steel Decking Concrete Floor Detail

compensating concrete slabs-on-ground. The design of suspended floors should conform to requirements of ACI 318 and ACI 421.1R. See Section 1.2 for relevant work by these and other committees. This guide identifies the various classes of floors as to •Use; • Design details as they apply to construction; • Necessary site preparation; and

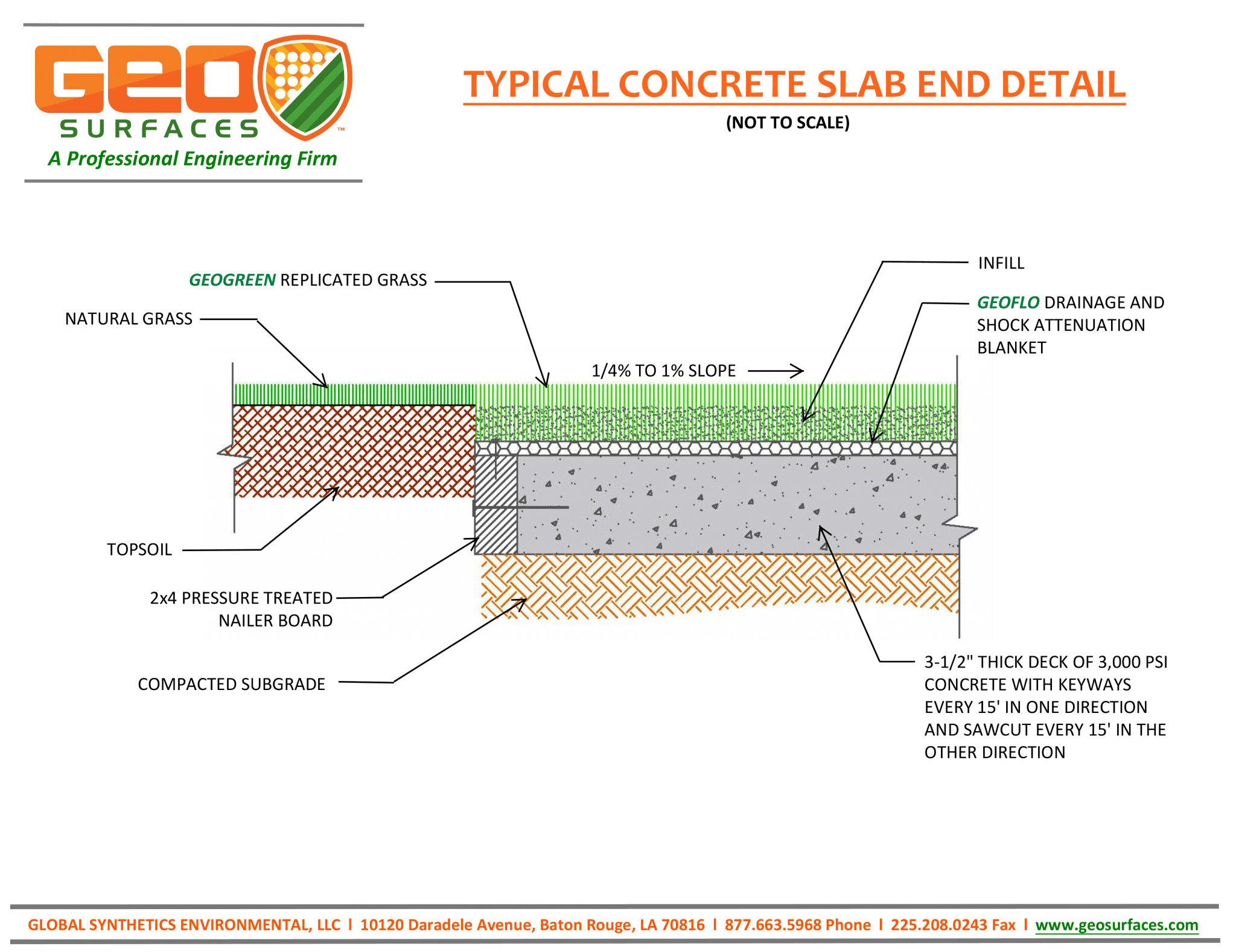

Cross Sections GeoSurfaces

Nominal cover of 25mm should be provided between the underside of the slab and the main bars. Concrete mix should be 30N20. Supporting rising walls and slab bearing should be at least 100mm. Table B5 - Appropriate slab depths and reinforcement mesh types for typical domestic ground floor slabs.