Concrete Floor Beams And Blocks Flooring Tips

Looking for the perfect flooring solution? In this comprehensive guide, we'll walk you througheverything you need to know about beam and block flooring. From.

How Much Does a Block and Beam Floor Cost in 2024? Checkatrade

Precast concrete beams are used in beam flooring, whereas precast concrete blocks are used in block flooring. The span of the system, the depth of the floor, and the overall cost are just a few effects of this difference. Fewer beams are needed to support the same area because beam flooring typically spans greater distances than block flooring.

Building an Extension 3 Suspended Beam & Block Floor YouTube

Beam and block flooring is a type of flooring system that consists of precast concrete beams and blocks. It is commonly used in both residential and commercial buildings as a cost-effective and efficient way of creating a solid and durable floor structure. The system works by placing precast concrete beams horizontally across the span of the.

filling door threshold cavity DIYnot Forums

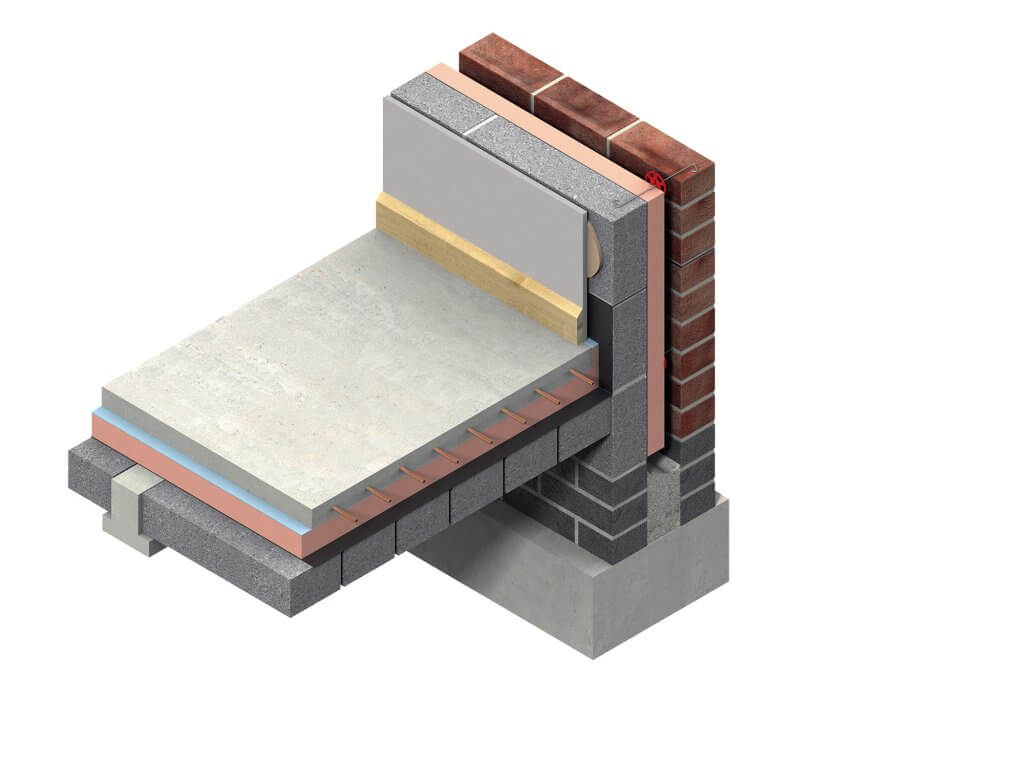

Beam & block floors. Bison Precast beam and block flooring system is quick, easy and economical to install. It offers numerous advantages, including improved acoustic performance and fire resistance. It is particularly suitable for intermediate flooring for houses where sound reduction, fire resistance and thermal mass are amongst its key benefits.

Introduction to Beam and Block Floors construction, detailing and selection

Precast Concrete beam and block floors are the cheapest, fastest and most robust way to create a solid floor. To make a beam and block floor, you first lay a.

The Benefits of Beam and Block Flooring Build It

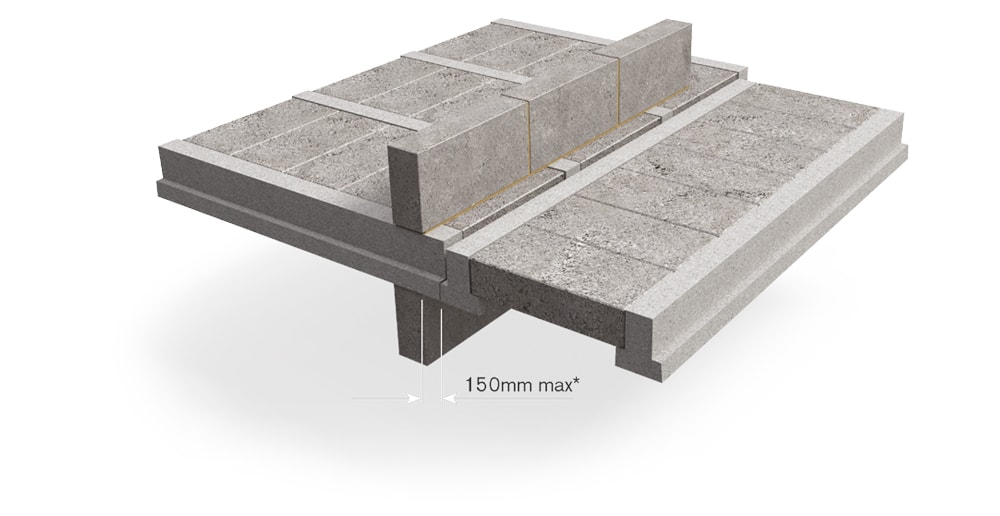

Installing Ground Floors. A minimum void of 150 mm must be provided between the soffit of the floor and the solum and a continuous damp proof course must be laid beneath the beam ends. Infill blocks to be aerated, aggregate or concrete, 440 x 215 x 100 mm. Minimum compressive strength of 3.5 N/mm² or 7.0 N/mm² with a traverse load capacity of.

Concrete Floor Beams Supplier Flooring Site

11 Installation Guide 12 Beam and Block Laying Guide 14 Commercial Ground and First Floor 15 Commercial Load Span Tables 16 Ventilation and C-Clips 18 Frequently Asked Questtions 19 Total Customer Satisfaction. Screeded beam and aircrete block flooring 807280031 A+

Beam and block floor Beams, Impact, Flooring, Building, Wood, Projects, Crafts, Log Projects

In this video Tony explains How to Lay Block and Beam for this two storey extension project. He talks through the plans supplied by Litecast, for this type o.

Block And Beam Floor Construction Viewfloor.co

guidance for beam and block ground floors. For detailed design guidance and requirements for regulatory/warranty compliance, refer to further guidance listed on the back page. Our series of Easy Guides for Housing is available at modernmasonry.co.uk Introduction: Beam and block ground floors Beam and block ground floors are the most commonly

Piled foundation with block and beam floor DIYnot Forums

Hooka lifts and carries heavy block and beam floor components from kerbside to installation; Safely lifts and installs beams over 300kgs; Huge labour cost savings, just 2 men needed on site for block and beam floor installations; The tracked base of the Hooka ensures excellent stability and minimal ground damage

Block and Beam Bring it on! ReVamp Diaries

Nudura provides a variety of Installation Manuals and materials to help with design specs, product lists, training, and installation.. 152 mm Form Block and Beam Floor Connection Detail at Grade Non-Brick Finish . CE-6. DWG. PDF. 152 mm Form Block and Beam Floor Connection Detail at Grade Brick Veneer Finish.

Precast Beam & Block Flooring Systems Bison Precast Forterra

An enduring trend in modern construction, block and beam floor installation presents itself as a remarkably durable flooring solution.Embracing this method, the UK building methods have seen a substantial shift towards more resilient and reliable construction techniques. This guide aims to provide a comprehensive overview of the process involved in installing a block and beam floor, offering.

Beam And Block Floor Suppliers Uk The Best Picture Of Beam

Application guide for the specification and installation of concrete toppings to beam & EPS block suspended floors September 2017 Page 3 2. Concrete type Two types of concrete are typically used to form the topping above the beam and EPS block system. In both cases the minimum strength class is C25/30 and should ideally have

Introduction to Beam and Block Floors construction, detailing and selection

Beam & Block is a robust solution for cost efective suspended loors. It is suitable for use on ground and upper loors on all kinds of construction, from residential to commercial buildings. The system is quick, easy and economical to install and offers numerous advantages including improved acoustic performance and ire resistance.

Introduction to Beam and Block Flooring Beams, Flooring, Architecture details

The beam and block floor offers good flexibility with thermal performance. High levels of rigid insulation can be installed over the beam and block floor. However, if EPS blocks are used, the floor system can achieve excellent thermal performance. Resistance to passage of sound. The inherent mass and damping qualities of concrete give beam and.

Pin on devon

Installation. Foundation walls must be accurately constructed so that the beam bearing ends are well supported on the inner leaf but do not overhang into the cavity. On ground floors a continuous damp-proof course must be laid along the top of the support wall, before the beams are lifted into position. To ensure a clean bearing on the support.

- Mens Leather Coats 3 4 Length

- Brushed Cotton Pyjama Bottoms Ladies

- Farms For Sale In Buckinghamshire

- Confetti Cannons For Gender Reveal

- Chain Saw Sharpening Near Me

- I Love Penguins Cute Figures

- End Of 20mph Zone Sign

- Early Years Educator Level 3 Mock Test Answers

- Thing That Is Good In Parts Crossword Clue

- Hope Has A Happy Meal